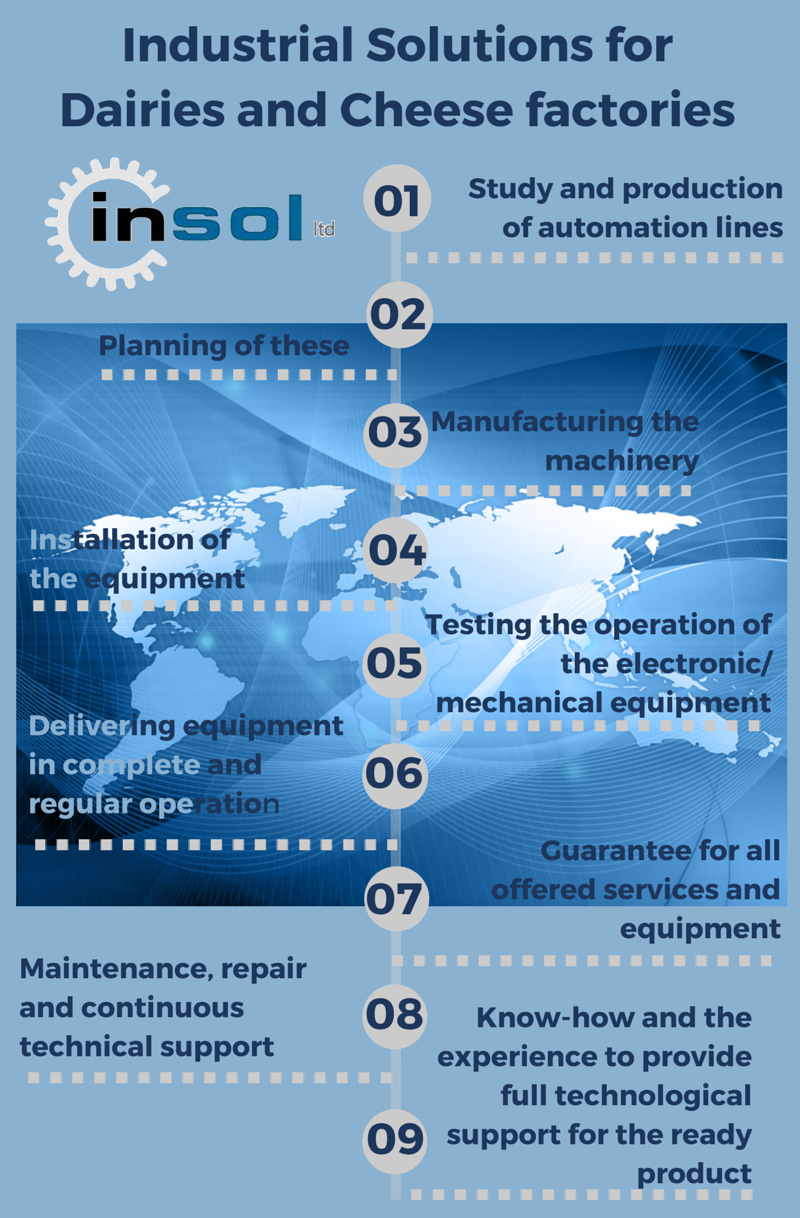

Insol ltd is a leader in the dairies sector in Greece and word wide. Our services include white and Feta cheese production lines, Greek traditional yoghurt's line and all kinds of machinery regarding milk and dairy plants, including know-how.

14 December 2015

26 November 2015

18 September 2015

07 August 2015

02 June 2015

Halloumi, Feta & Yogurt Project in New Zealand

28 May 2015

21 May 2015

Feta and yogurt project in North America

One more

time the Greek products were the favorite ones and a new dairy has been called

to complete this demand of consumers in North America by

offering the authenticity of a Greek product that is made by the machinery and

know-how of Insol ltd.

Feta cheese, yogurt,

yogurt with fruits, yogurt with vegetables like the favorite tzatziki!

Ετικέτες

cheese,

feta,

new project,

North America,

yogurt

19 May 2015

28 April 2015

06 April 2015

27 March 2015

Greek Yogurt Production Line

Ετικέτες

dairy,

Greek yogurt,

production line,

yogurt

26 March 2015

Feta Cheese Multi Block Forms

18 March 2015

09 March 2015

03 March 2015

01 March 2015

Molds' Turner

The turning of the mold’s stack is a very important process during the draining and forming procedure of the cheese block. The shape and structure of the blocks are defining the final product. Avoiding the phenomenon of "wedge" at the block is what Insol ltd can confirm and obtain by the ground molds turner. The time and manner of rotation are the main reasons of success.

25 February 2015

17 February 2015

16 February 2015

Kasseri Production Line

For the production and process of the Kasseri cheese, Insol ltd provides

the automatic equipment for the filling, maturation, de-molding and

packaging of the product.

Ετικέτες

automatic,

cheese,

dairy,

kasseri,

maturation,

yellow cheese

11 February 2015

De-stacker & Molds washing machine

Starts the

de-stacking and one to one the multy block forms put the empty blocks of cheese

on the conveyor so that the operator takes them manually

and place them in containers for storage. Then the empty mold is guided into

the washing machine for washing.

The mold is automatically moved at various stages of washing, which are separated from each other by special plastic curtains for preventing movement of liquid and heat from one stage to another. Washing at each stage over a network of special spray nozzle where are conveniently positioned for the perfect cleaning of the mold.

Washing is

completed in four steps:

·

First

stage is the prewash with natural water under pressure, and various spraying

angles.

·

The

second washing step is washing the mold with a chemical solution

·

The

third step is washing (rinsing) the mold by the chemical solution with natural

water.

·

The

fourth and final step of washing is the final rinsing with natural water.

And from there the mold is automatically or manually removed from the single output of the washing machine.

Ετικέτες

blockforms,

cheese,

de-stacker,

feta,

machine,

molds,

washing

Subscribe to:

Posts (Atom)